TL;DR — Why This Matters

Every year, ladder accidents cost U.S. businesses over $24 billion and injure more than 22,000 workers, making falls from height one of the most preventable yet persistent causes of workplace harm. This research distills the latest OSHA, CDC, and National Safety Council data (2020–2025) and reveals a simple truth: most of these incidents are no longer necessary. Through modern aerial inspection technology, companies can remove the worker from the risk entirely, achieving up to 90% fewer fall-related incidents while cutting inspection costs by 25–35%.

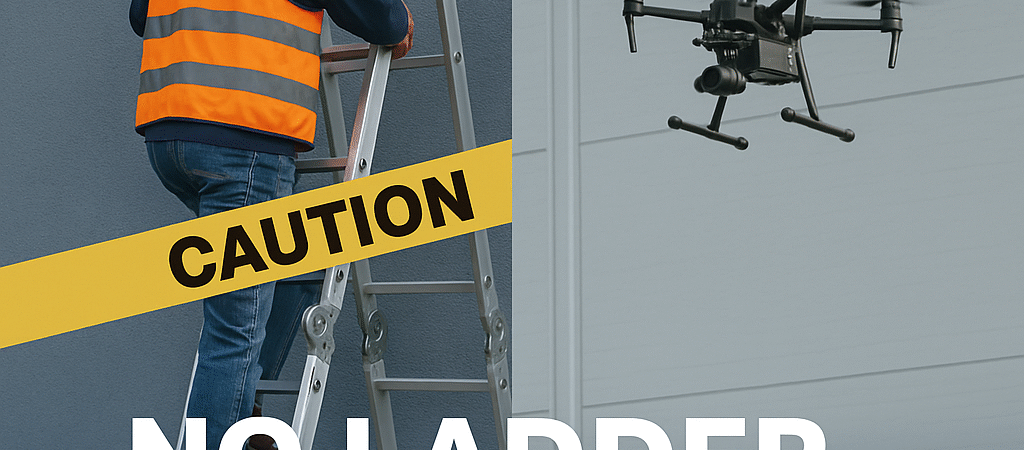

Whether you manage facilities, insurance portfolios, or job sites, this data shows how drone adoption is no longer a futuristic upgrade—it’s an immediate financial and ethical imperative that turns “No Ladder. No Liability.” into a measurable standard of care.

Ladder Fall Injuries and Fatalities (2020–2025)

Falls from ladders remain a serious workplace hazard in the U.S. Recent data show that in 2020 alone there were 161 workplace fatalities and 22,710 nonfatal ladder injuries requiring days off workcdc.gov. (By comparison, 2019 saw 171 fatal ladder falls, indicating a slight declinebls.gov.) These incidents are especially frequent in construction, maintenance, and repair occupationscdc.gov. In fact, ladder-related falls constitute a large share of fatal falls from height – one analysis found two-thirds of deadly falls in construction involve roofs, scaffolds, or laddersbicmagazine.combicmagazine.com. Men, older workers, and Hispanic workers (often in construction) experience higher ladder fall injury ratescdc.gov. Notably, most ladder falls occur from relatively low heights (under 10 feet) yet can still be fataltowerstreetinsurance.com. The persistence of ladder injuries has kept “Ladders” among OSHA’s top 5 most-cited safety violations in recent yearstowerstreetinsurance.com, underscoring the need for improved fall prevention measures.

Financial Burden of Ladder-Related Accidents

Ladder accidents impose a substantial economic cost. Each year, over 500,000 people in the U.S. require emergency medical treatment for ladder injuries, and about 300 die (including both work and home incidents)blogs.cdc.gov. The estimated annual cost of these ladder injuries is $24 billionblogs.cdc.gov. This figure includes direct costs like medical bills and workers’ compensation, as well as indirect costs such as lost productivity, legal/liability expenses, training replacement workers, and pain & sufferingtowerstreetinsurance.comtowerstreetinsurance.com. To put it in perspective, the National Safety Council (NSC) reports that the average cost per medically consulted work injury is about $43,000, and per work-related death is $1.46 millioninjuryfacts.nsc.org. Preventing even a single serious ladder-fall injury therefore yields tens of thousands of dollars in savings on medical treatment, lost work time, and accident investigations. The National Safety Council notes that these cost estimates reflect the broader societal impact (not just employer costs)injuryfacts.nsc.orginjuryfacts.nsc.org – meaning a severe fall affects not only the injured worker and their employer, but also the economy through lost output and healthcare burden. In short, ladder accidents are not only a significant cause of occupational harm, they also carry a hefty financial price tag for organizations and society.

Drones as a Fall-Prevention Solution (Safety Gains)

To reduce ladder-related accidents, safety experts are turning to technology that eliminates the need to climb in the first place. One promising approach is using drones (unmanned aerial systems) for tasks like inspections, surveying, and maintenance checks that would traditionally require a worker on a ladder or scaffold. Research by the National Safety Council highlights that drones can effectively “remove the worker from the height altogether,” thereby virtually eliminating the risk of a fall in those tasksnsc.org. In other words, if a drone’s camera can inspect a roof, tower, or industrial equipment from the air, a human doesn’t have to physically ascend – the worst-case scenario then becomes a damaged drone instead of a worker injuryrospa.com. This approach follows the highest principle of workplace safety: hazard elimination. By keeping workers on the ground, drones provide a fundamental safety gain – preventing falls by preventing exposure to heights.

Studies and industry pilots are beginning to quantify the benefits. According to one safety analysis, drone-based inspections can reduce the time needed by ~30% and cut inspection costs by ~25% compared to traditional manual methodsstandingseamroofanchor.com. Drones equipped with high-resolution cameras and sensors can quickly reach areas that might be slow or dangerous for workers to access with lifts or ladders. This efficiency not only improves productivity but also means workers spend less time in potentially precarious positions. Early evidence also suggests improvements in quality and accuracy – drones can capture detailed imagery and data, helping identify issues without human error from precarious vantage pointsstandingseamroofanchor.com. All of these gains (efficiency, cost savings, and data quality) come in addition to the primary safety benefit: keeping workers off ladders and roofs. In short, drone technology offers a win-win: it significantly reduces fall risk while often speeding up the work and lowering costsstandingseamroofanchor.comstandingseamroofanchor.com.

Safety and Efficiency Gains: Real-World Examples

A drone operator performs an inspection of an elevated structure from the ground. By using drones for such high-risk tasks, companies can avoid putting workers on ladders or scaffolds.

A growing number of organizations have begun adopting drones as a proactive fall-prevention measure. Jacobs Engineering, a large technical services firm, provides a compelling case study. In 2023–24, Jacobs implemented a drone inspection program to replace many tasks that previously required engineers to climb scaffolding up to 50 meters high (such as checking equipment on a power station)rospa.comrospa.com. Now, instead of working at height, Jacobs inspectors pilot drones from the safety of the ground, dramatically reducing their exposure to fallsrospa.com. “Drones completely remove humans from the working-at-height risk,” explains Jacobs’ Head of HSE, noting that this innovation eliminates the most common cause of fatal workplace accidentsrospa.com. The safety impact is clear – the risk of a catastrophic fall has essentially been engineered out of the processrospa.com.

Jacobs also reports significant efficiency and cost benefits from this approach. For example, one required inspection of a tall chimney would have normally necessitated building extensive scaffolding over months. Using a drone, the same inspection was completed in just 30 minutes of flight time, with all necessary data collectedrospa.com. “Not only did this save thousands of pounds in scaffolding and man-hours, but it also saved months of time… and I was not at risk of falling from the structure,” noted the Jacobs drone pilotrospa.com. In essence, the drone accomplished in minutes – with zero risk – what traditionally would have been a multi-month, high-risk ladder/scaffold job. Such outcomes earned Jacobs recognition as a finalist for the 2024 RoSPA Fall Prevention Trophy, highlighting how technology can transform work-at-height safetyrospa.comrospa.com. Other companies in construction, utilities, and insurance inspections are seeing similar benefits, using drones to inspect roofs, cell towers, and facades – thereby keeping workers off ladders.

Even regulators have embraced this trend. OSHA has begun using drones for its own inspections in situations where sending an inspector might be hazardous. In 2018 OSHA formalized a policy to deploy drones with cameras to survey dangerous or hard-to-access areas during enforcement inspections (e.g. after major incidents), rather than putting a compliance officer at riskbicmagazine.com. As of 2020, OSHA had a fleet of about 12 drones across its regions to assist in inspections, used with employer consent to document conditions from abovebicmagazine.com. OSHA officials have stated that drone technology is a key tool in improving safety and plan to expand its use, as it “continues to be a part of our mission to ensure the safety and health of workers”bicmagazine.com. NIOSH research initiatives echo this approach – for instance, developing drone-based hazard detection systems (e.g. spotting missing guardrails) to proactively prevent falls on construction sitesnsc.org. All of these efforts reflect a growing consensus: removing the ladder from the equation – by using drones or other remote methods – can eliminate a major source of workplace injuries and liability. In sum, “No ladder, no fall, and no fall-related liability” is becoming a new safety mantra backed by both data and real-world success stories.

Sources

- CDC / NIOSH – Ladder Safety Statistics (2020): Key facts on workplace ladder fatalities (161 deaths) and injuries (22,710 cases) in 2020cdc.gov. Highlights higher-risk occupations and the prevalence of ladder falls in construction and maintenance roles.

- CDC – National Ladder Safety Month Blog: Overview of the ladder fall problem: 500k injuries and ~300 deaths annually in the U.S., with an estimated $24 billion yearly cost (direct and indirect)blogs.cdc.gov. Explains that ladder injuries are a serious and costly public health issue.

- National Safety Council – Work Injury Cost Data (2023): Provides average economic costs per injury and fatality. Estimates ~$43,000 per medically consulted injury and $1.46 million per death, reflecting the high cost savings for each fall preventedinjuryfacts.nsc.org.

- NSC Safety Technology Report (2020): Explores how emerging technologies reduce risks. Notes that drones eliminate fall-to-lower-level hazards by keeping workers off ladders, particularly for elevated inspectionsnsc.org. Emphasizes removing the human from the height as an ideal control measure.

- Industry Analysis – Drone vs. Traditional Inspections: Findings that drone inspections cut job time ~30% and lower costs ~25%, while minimizing disruptionstandingseamroofanchor.com. Demonstrates that using drones can improve both safety and efficiency compared to manual ladder inspections.

- RoSPA Case Study – Jacobs Engineering (2024): Details how Jacobs implemented drones to replace scaffold/ladder work. Resulted in zero height exposure for inspectors and large savings in time and moneyrospa.comrospa.com. Quote: “Drones completely remove humans from the working at height risk,” confirming a major reduction in fall potentialrospa.com.

- OSHA HSE Update – Drone Usage (2020): Reports that OSHA is leveraging drones for certain inspections to avoid putting inspectors in harm’s waybicmagazine.combicmagazine.com. By 2020, ~12 OSHA drones were in operation for compliance audits, illustrating institutional support for drone-based fall prevention.